All Tooling was inspected and found to be in good condition.

Processed .09" AL - cosmetic material.

Bend Length = 76"

Flange Height = 6.5"

Max Thickness = .098" MS .083" SS .126" AL

CLA-A Thickness = .079" MS .06" SS

CLA-A Length = 13" ea Total = 26.38"

CLA mover is working but the tooling is not on the machine - can be purchased

Under Power Running Production

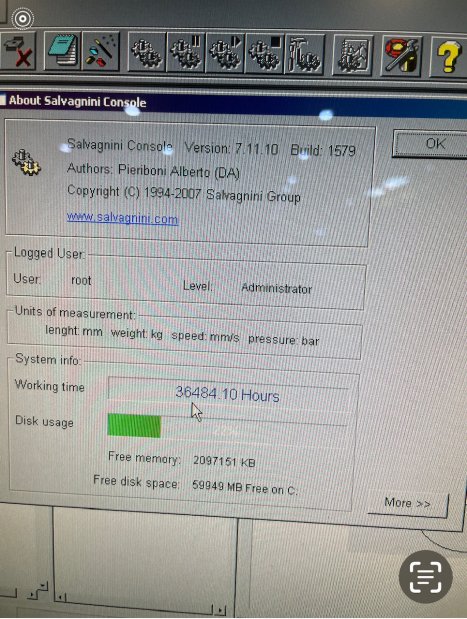

Approx. 36,500 hours

PERformER+

PERformER+ Panel Bender

LI Lower bending blade

LS1 Upper bending blade

SiX Control system

JOB.CONSOLE.P4 Software for managing the production and the P4 system

CLA-A Auxiliary bending tool asymmetric command for positive bends

PERformER+ - Panel Bender

Programmable and automatic machine for the production of sheet metal panels

through the formation of a number of bends on each of the four sides.

The machine has the following specifications:

-numeric control of the sheet centering references on both axes; automatic

set up of the references;

-ability to produce the first bend flattened at 180 degrees (positive and

negative safe edge);

-ability to program the stop of the descending blankholder from 0 to 6.496"

(165 mm) in order to obtain, for example, an open safe edge;

-maximum number of bends on each side: free;

-ability to make both upwards and downwards bends, but the last bend on each

side must be an upwards bend;

-ability to bend pre-painted sheets or silked stainless steel, when protected

by plastic film (however, the quality of the material must be verified

according to the application);

-discontinuous rotator at 90, 180 and 270;

-the blankholder is equipped with left and right contractible end segments, which allow the production of two different bending lengths within the same cycle, without intervention of the operator -an electrical coil can be programmed, by means of graphic interface software (Oil Heating), to come on so as to bring the oil in the hydraulic circuit to the working temperature at a programmed time (it only works when the power

cabinet is on);

-work surface equipped with circular inserts with plastic brushes; it allows

the panel to be moved easily without marking the contact surface and reduce

the noise level during the production cycle;

-hermetically insulated power cabinet provided with an automatic device for

the ventilation and the internal temperature control;

Cooling

Two independent closed cooling circuits are installed in the machine.

Oil cooling circuit

An oil-air-cooler is installed to maintain a constant oil temperature in the

hydraulic circuit. The specific refrigerating capacity is 0.5 kW/K. That

corresponds to 10 kW refrigerating capacity at a difference in temperature of

20 K.

b)Electrical cabinet cooling circuit

A cooling unit with a refrigerating capacity of 0.8 kW is installed to

maintain a constant temperature inside the electrical cabinet. The ecological

refrigerant R134a is used in this cooling circuit.

Programming:

The programming can be made directly on the elaboration unit of the system

without interrupting the current working cycle. The language is high

level; the defined macroinstructions express geometrical concepts (ANGLE,

RADIUS, LENGTH). The post- processor is included; it analyzes the syntax and

the geometry of the programming macroinstructions, transforming them in data

useful to the working cycle of the PERformER+, furthermore it manages the

movements of the manipulator, also considering the forming of the sheet metal,

and it automatically calculates the gripping points;

A graphic user interface simplifies the use and programming of the machine.

Operational characteristics

maximum length of incoming notched sheet:78.74"(2000 mm)

maximum width of incoming notched sheet:59.06"(1500 mm)

maximum diagonal of notched sheet:84.65"(2150 mm)

maximum bending length:76.77"(1950 mm)

maximum dimension of bends above work surface:6.496"(165 mm)

LI - Lower bending blade

Bending blade able to make positive bends up to +135 in a single step.

Maximum thickness of sheet metal with

UTS of 59.5 ksi (410 N/mm2) (+ 90)0.098"(2.50 mm)

UTS of 59.5 ksi (410 N/mm2) (+ 135)0.083"(2.10 mm)

UTS of 84.1 ksi (580 N/mm2) (+ 90)0.083"(2.10 mm)

UTS of 84.1 ksi (580 N/mm2) (+ 125)0.063"(1.60 mm)

UTS of 38.4 ksi (265 N/mm2) (+ 90)0.126"(3.20 mm)

UTS of 38.4 ksi (265 N/mm2) (+ 135)0.083"(2.10 mm)

Minimum thickness of sheet metal0.020"(0.50 mm)

LS1 - Upper bending blade

Bending blade with reduced front dimensions, able to make negative bends up to

-135 in a single step.

Maximum thickness of sheet metal with

UTS of 59.5 ksi (410 N/mm2) (- 90) 0.098" (2.50 mm)

UTS of 59.5 ksi (410 N/mm2) (- 135) 0.083" (2.10 mm)

UTS of 84.1 ksi (580 N/mm2) (- 90) 0.083" (2.10 mm)

UTS of 84.1 ksi (580 N/mm2) (- 125) 0.063" (1.60 mm)

UTS of 38.4 ksi (265 N/mm2) (- 90) 0.126" (3.20 mm)

UTS of 38.4 ksi (265 N/mm2) (- 135) 0.083" (2.10 mm)

Minimum thickness of sheet metal 0.020" (0.50 mm)

SiX - Control system

High performance proprietary control system distributed on 3 levels.

- Elaboration unit for managing and supervising the machine. The unit is

composed of a HP workstation with Windows XP Professional (English) operation

system equipped with: SATA hard disk, two ETHERNET TCP/IP network cards, UTP

cable with RJ45 connector and analog modem for information exchange between

the system and various Salvagnini depts. such as Service, Automation, Studies

& Applications.

The workstation is equipped with HW and SW System Backup package composed of an RHD (Removable Hard Disk) and of the management software that allows the customer to automatically backup the whole main HD into the new RHD support.

The operator is automatically and periodically reminded to carry out the

backup procedure by video warnings

The workstation, which is an integral part of the SiX control system, is

tested and configured according to exact Salvagnini specification to

communicate with the control unit and grant remote service. The hardware and

software configurations cannot be modified by the customer.

-Control unit which communicates in real-time with the interface section

through a high- performance VME bus and a field bus (Ethernet o CANopen).

-Input/output interface section towards peripheral devices such as motors,

solenoid valves, sensors, etc.

The UPS (Uninterruptible power supply unit) installed inside the system power

cabinet allows the Six control and the elaboration unit to be correctly shut-

down in case of sudden blackouts.

JOB.CONSOLE - Software for managing the production and the P2

JOB.CONSOLE is the set of software packages integrated in the SiX control

system, which graphically allows the system to be easily used, managed and

supervised by supplying you with all the information required to carry out

production.

Furthermore, the information relevant to system operation is collected and

arranged in order to make it available for a correct system monitoring.

JOB.CONSOLE includes the following modules:

Salvagnini Console

Main console for an intuitive management of the system which allows you to:

-easily save and find programs thanks to graphic tree structure

-use an editor for a simple correction of the programs

-semi-automatically move parts of the system, by means of a graphic

interface, useful to easily use or access the system.

JOB P4

Application used to dynamically schedule daily production; you can create a

sequence of programs named "job" or list, on screen. JOBP4 allows you to queue

and modify the sequence of jobs without waiting that the job being processed

is finished. The production can be interrupted and then re-started from where

it was interrupted. The programs that require a manual changeover of the

system setup must be grouped in separate Jobs.

Salvagnini Compiler

The Salvagnini compiler interprets programming instructions based on

geometrical principals (e.g.: finished dimension of the panel, length of the

edge to be bent and angle to be obtain on each bend) and defines the

production cycle calculating sheet metal handling and cycle time. The compiler

supplies the dimensions of the unfolded, information on program integrity and

suggestions on wrong info. Moreover, it can simultaneously compile groups of

programs arranged in work directories.

Maintenance Manager

Database of the analyses of the movements and cycles of the system components

for an easy maintenance and wear checking of some parts; it includes a list of

maintenance checks to be performed. You can add further checks or alarms to

parts of the system.

EasyData

Diagnostic software integrated with the NC to interactively browse

documentation using "web" technology (photos, hyperlinks, part code and

automatic filters).

EasyData supplies information pertaining to each component managed by the

Salvagnini NC. The system wiring or fluid-mechanical diagrams can be looked up

directly on screen, automatically filtered on the component being diagnosed or

by text searching the documentation.

You can also:

-enrich the photo library with your own photos or notes

-print one or more documental diagrams on paper or export them in PDF or JPG

EasyData does not contain the documentation of any third party components

integrated in the Salvagnini systems.

CLA-A - Auxiliary bending tool asymmetric command for positive bends

Option of the panel bender composed of two NC devices able to independently

and asymmetrically position the auxiliary bending tools along the lower blade

in order to make bends with interrupted bending edge (e.g. welding tabs).

The auxiliary bending tools (set of CLA tools) are not included.

Characteristics:

Maximum thickness of metal with UTS of 59.5 ksi (410 N/mm2) 0.079" (2.00 mm)

Maximum thickness of metal with UTS of 84.1 ksi (580 N/mm2) 0.059" (1.50 mm)

Maximum length of the pair of auxiliary bending tools (UC-P2) 12.99" (330 mm)

Maximum length of the pair of auxiliary bending tools (UC570) 26.38" (670 mm)

Minimum length of the pair of auxiliary bending tools (UC-P2) 1.969" (50 mm)

Minimum length of the pair of auxiliary bending tools (UC570) 3.937" (100 mm)

Maximum bend angle in a single step: 90

To view more information on the SALVAGNINI P2 PANEL BENDER,MFG:2008 OUR STOCK NUMBER: 12486, including reviews, brand information, photos, videos, and more,

Fill in the form below to see Seller Info.