Overview:

Type: Horizontal Band Saws (Semi-Automatic)

Category: Saws

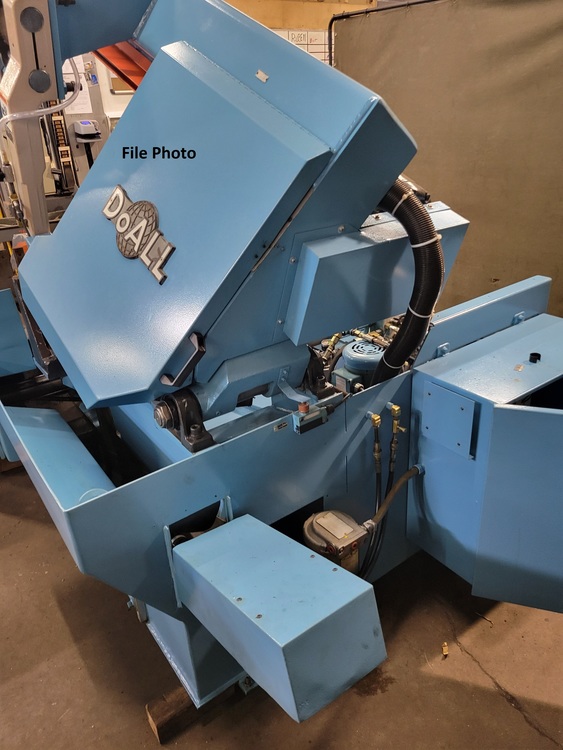

Manufacturer: DOALL

Model: C-4100NC

Condition: Used - Rebuilt

Stock #: 8278

Status: For Sale

Serial #: 514-94123

Description:

Doall Heavy Duty Workhorse model C-4100NC horizontal Fully automatic, programmable Bandsaw.

Extra Heavy design, 1 1/2" Blade, 7.5 H.P. Variable speed blade drive with programmable speeds,

Myers Technology Company Proprietary

50 Point Refurbishing and Repair Process

Myers Technology Company (MTC) carefully examines all major castings for cracks, wear, and weak point failure.

MTC tests all slide and pivot areas for proper alignment and functionality.

We start up and test run all equipment.

MTC ensures that all functions of both manual and auto cycles work properly.

We take note of any missing or failing parts and place orders for replacement parts that meet or exceed OEM standards.

Once the machine passes inspection on steps 1-5, MTC begins disassembly.

All guards are removed and inspected for wear or cracks.

All way covers are removed and ways and covers inspected for wear or tear.

Machine oil is drained, cleaned and replaced with new oil to proper levels and condition.

All vices, chucks, and other mechanical control items are removed, cleaned and inspected.

The machine is thoroughly cleaned using steam, degreasers, and solvents.

The hydraulic system is tested for noise.

The hydraulic system pressure is tested for proper settings.

The hydraulic system couplings are examined and aligned as needed.

The hydraulic system hoses are inspected and replaced as needed.

The hydraulic system valves are inspected and tested for proper function.

Electrical system wires are cleaned and examined for damage or wear, replaced as needed.

Electrical system switches are cleaned and inspected for damage or wear, replaced as needed.

Electrical system controls are cleaned and inspected for damage or wear, replaced as needed.

The electrical system cabinet is examined and cleaned.

Worn and failing elements of the hydraulic and electrical systems are replaced as necessary.

Bearings are inspected for proper function and measured for play.

Bearings are replaced as necessary.

Motors are inspected and rebuilt or replaced as necessary.

Motor couplings are removed, cleaned, and examined for wear and failure, replaced as necessary.

Belts are inspected for wear, cracks, and fraying and replaced as necessary.

Belts are inspected for proper alignment.

Gearboxes are cleaned and inspected.

Oil is drained from gearbox.

Gearboxes are refilled with proper oil to correct levels.

Chip conveyors are cleaned and inspected for wear.

Coolant systems are cleaned and inspected.

Worn and failing elements of the gearbox, conveyor, and coolant systems are inspected and replaced as necessary.

Hydraulic fluid is drained and replaced to proper levels in hydraulic system.

All filters are removed and cleaned or replaced.

Sheet metal is cleaned and inspected for wear and failure.

Safety switches are cleaned and tested for proper function.

Safety switches are replaced as necessary.

Machine is inspected to ensure steps 1-38 have been properly completed.

Unit approved for painting.

All previously painted surfaces are prepped and primed.

All primed surfaces are given 2 coats of industrial grade paint.

All systems are reassembled to complete the machine.

All buttons and switches on control works are inspected for wear and functionality.

Machine functions are tested for performance.

Machine is operated in full automatic mode.

Test cuts are completed and examined for accuracy.

If unit passes tests in steps 44-47, machine is calibrated.

A video of the machine is recorded.

Machine is prepped for proper shipping, tied down, Wrapped, etc.

Machine is given a 6 month Warranty.

There are many more items checked and repaired

This is a general description of Myers Co. process. MTC works on many different types of machines. This marketing document in no way constitutes a contract, written or implied.

Equipped With:

Programmable NC Control, Hydraulic Blade tension, Vises, variable vise pressure, rapid head approach, AC variable speed blade drive that is programmable, Chip conveyor and all available manuals, New Blade

Specifications:

Rect-Cap (H) 14"

Rect-Cap (W) 16"

Rounds-Cap 16"

Square-Cap 14"

Power 10 hp

Type (Auto, Manual, Semi) Semi

Blade Width 1.5"

Blade Thickness 0.05"

Blade Length 183"

Control CNC (Doall NC)

Dimensions 90" x 96" x 65" high

Weight 6,800 lbs.

Specification : Round Work Capacity 16" - Square Work Capacity 14" x 16"

Max Blade Size 1.5" x 186"

Blade Wheel Diameter 21"

Blade Speeds Variable 40 - 360 FPM

Stock Feed Shuttle Travel 24" Single Stroke / 999" Multiple IndexNumber of Shuttle Indexes

Drive Motor 10 HP

Coolant Capacity 20 Gallons

24" Stroking Stock Shuttle Vise Front Hydraulic Vise

Hydraulic Band Tensioning with Controls

12" Long Parts Drop Table

Chip Conveyor

Coolant System

Work Light

Electrics:460 Volt, 3 Phase

Approximate Machine Wt. 6800LBS