Overview

Type: Vertical Machining Centers

Manufacturer: HARDINGE

Model: GX1000 OSP

Year: 2011

Stock #: LKV

Status: For Sale

Serial #: NVCB1I0215

Country: United States

Description

The Hardinge Bridgeport GX 100 OSP is a high-performance vertical machining center designed for precise and efficient machining tasks. It combines the robust design of the Bridgeport series with advanced control systems like the OSP-P300 by Okuma. Below are its key features and capabilities:

Core Features:

High Rigidity Structure:

Rigid cast iron construction to minimize vibration and ensure high accuracy during heavy machining.

Designed for durability and long-term precision.

Spindle:

High-speed spindle 10,000 RPM Direct-drive spindle design for reduced vibration and better surface finish.

Suitable for a variety of materials, from aluminum to harder steels.

Tool Changer:

Automatic tool changer (ATC) with a capacity of 24 to 30 tools, depending on the configuration.

Fast tool change times to minimize downtime.

Work Envelope:

Generous travel ranges for machining large components:

X-Axis: ~1,020 mm (40 inches).

Y-Axis: ~540 mm (21 inches).

Z-Axis: ~610 mm (24 inches).

Large table size for accommodating bigger workpieces or multiple setups.

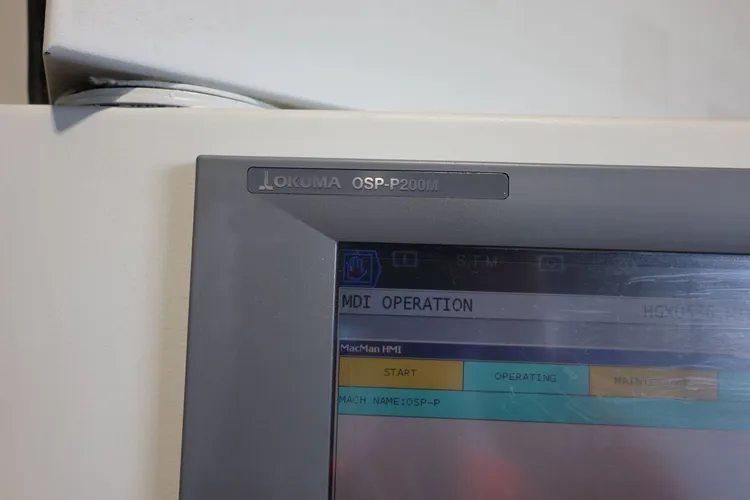

Control System (Okuma OSP-P300):

User-friendly and highly reliable CNC control system with powerful capabilities for complex machining operations.

Integrated conversational programming for simplified setup and operation.

High-performance processing for faster and more accurate machining.

Precision Ball Screws and Linear Guides:

High-quality components ensure smooth motion and reduced wear over time.

Enables tight tolerances and excellent repeatability.

Coolant System:

Integrated high-pressure through-spindle coolant system for effective chip evacuation and enhanced tool life.

Multiple coolant nozzles for optimal cooling.

Chip Management:

Efficient chip conveyor system to handle large volumes of chips and maintain a clean work environment.

Advanced Safety Features:

Fully enclosed machining area to protect operators and maintain clean surroundings.

Automatic shutdown and alarms for operator safety and machine protection.

Located at our warehouse in Preston, Idaho